Product Documents

TPRC™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

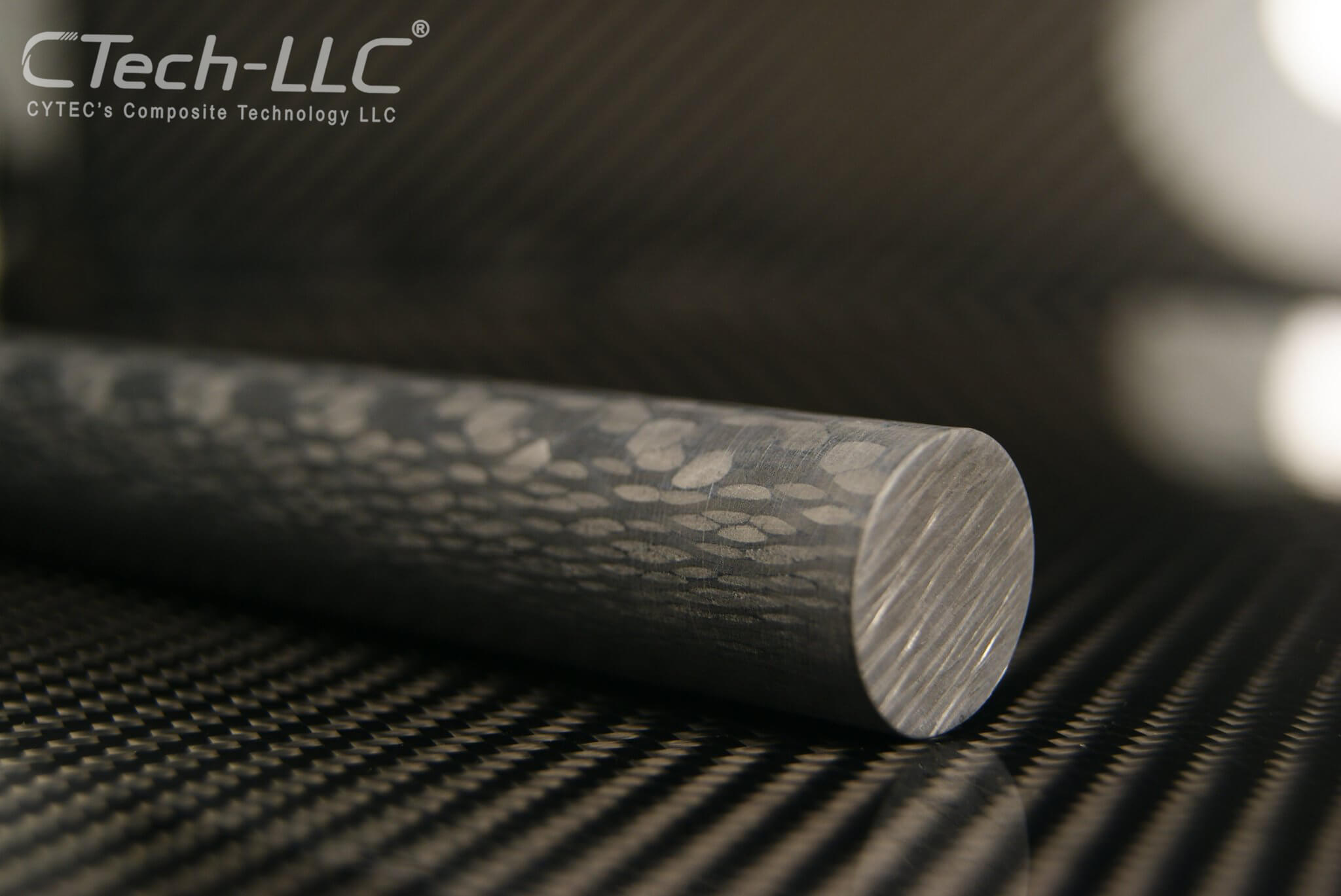

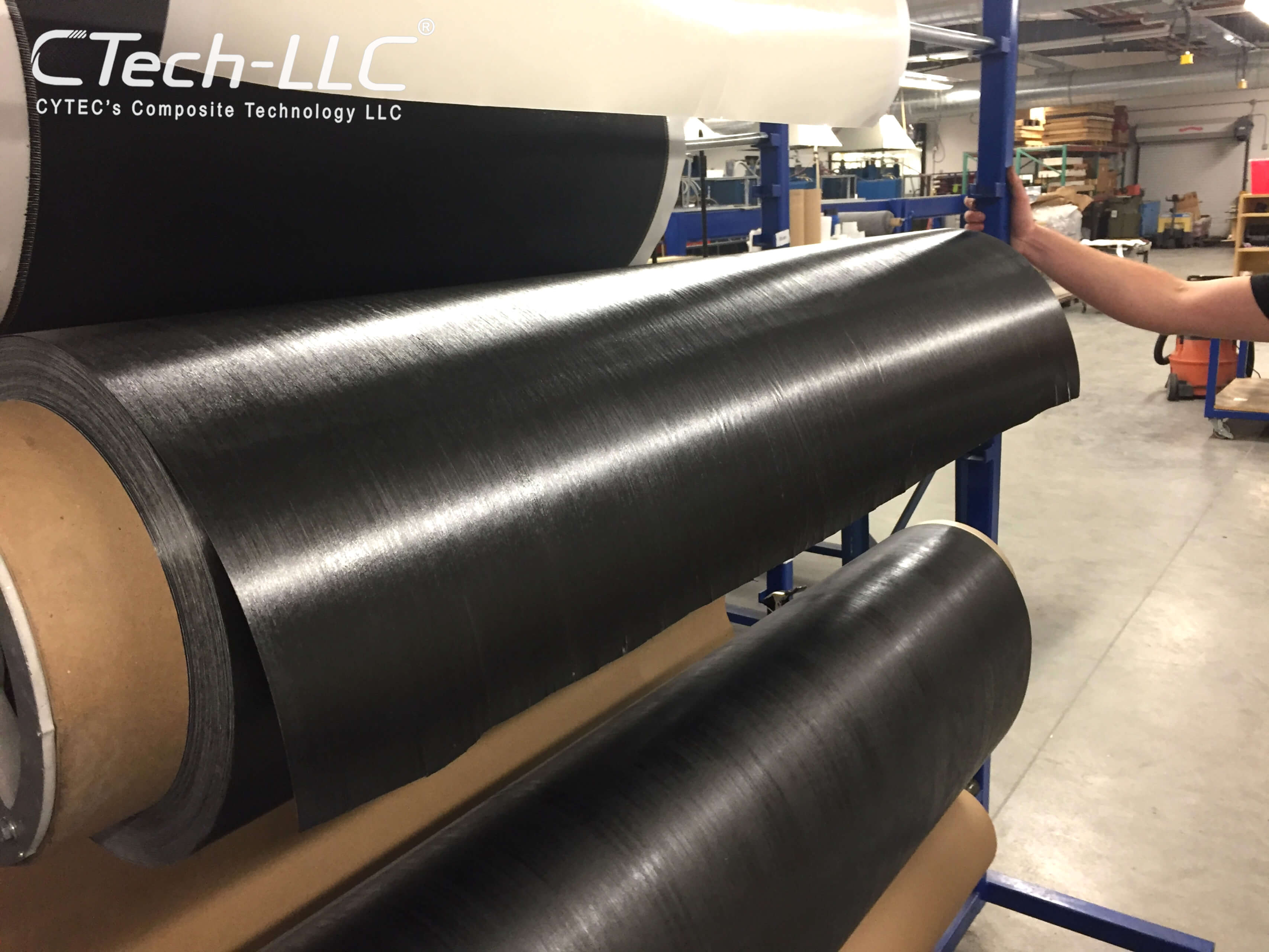

CTech-LLC® TPRC™ ThermoPlastic Reinforced Carbon are becoming increasingly popular in highly cost-driven markets. CTech-LLC® TPRC™ Thermoplastic Reinforced Carbon consist of a thermoplastic matrix combined with various reinforcing materials such as short, long or continuous carbon fibers. Processes for the production of thermoplastic composites include injection molding, compression molding, tape placement, winding and thermoforming.

Key Features

- Integrated component design

- Short cycle times and flexibility of processes

- Automation and large-scale production

- Recycling opportunities

Applications

- Advanced composites

- Airbag Housing Combination of injection molding and thermoforming of organo sheets in a one-shot process Sporting

- Engine Compartment Protection with Compression molding process Primary Structures.

- Composite Panels with Lightweight material, high mechanics and weather resistance that improves the cost-efficiency and reduces the environmental impact.

- Rear Muffler Cover with Compression molding.

Storage Conditions

- The shelf life is 6 months from the date of manufacture when the maximum storage temperature shall not exceed 32°C.

- The shelf life is 12 months from the date of manufacture when the maximum storage temperature shall not exceed 24°C.

- The shelf life is 30 months from the date of manufacture when the maximum storage temperature shall not exceed -18°C, with an

- additional 6 months at <24°C.

Shelf Life

Shelf life is 3 years.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.