Product Documents

UCW™ - Technical Data Sheet BCW™ - Technical Data Sheet Safety Data Sheet Testing GuideFor more information regarding CTech-LLC® products, please contact our team by clicking here.

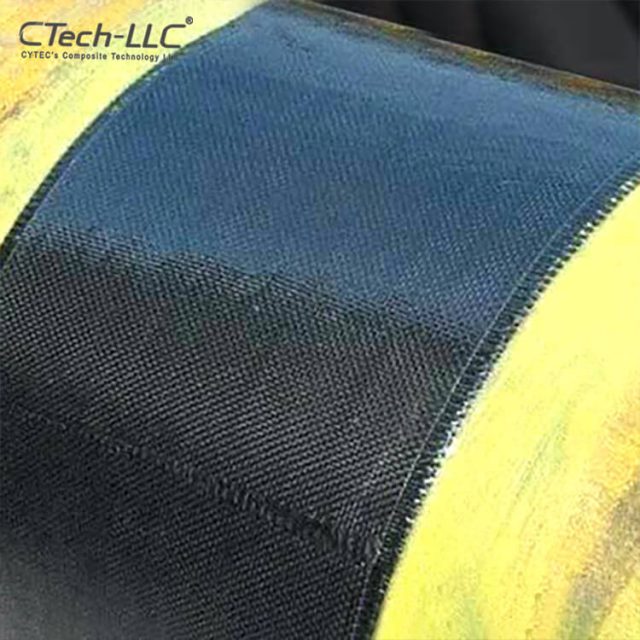

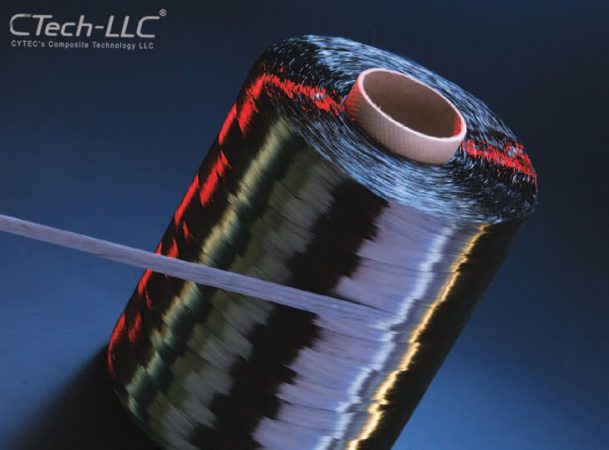

The CTech-LLC® Carbon Wrap is high strength carbon fabric designed for structural reinforcement applications as part of the CTech-LLC® FRP strengthening system. A wide range of uni-directional and bi-directional carbon fabrics in different weights are available for installation using the dry or wet application process to meet the specific requirements of each project.

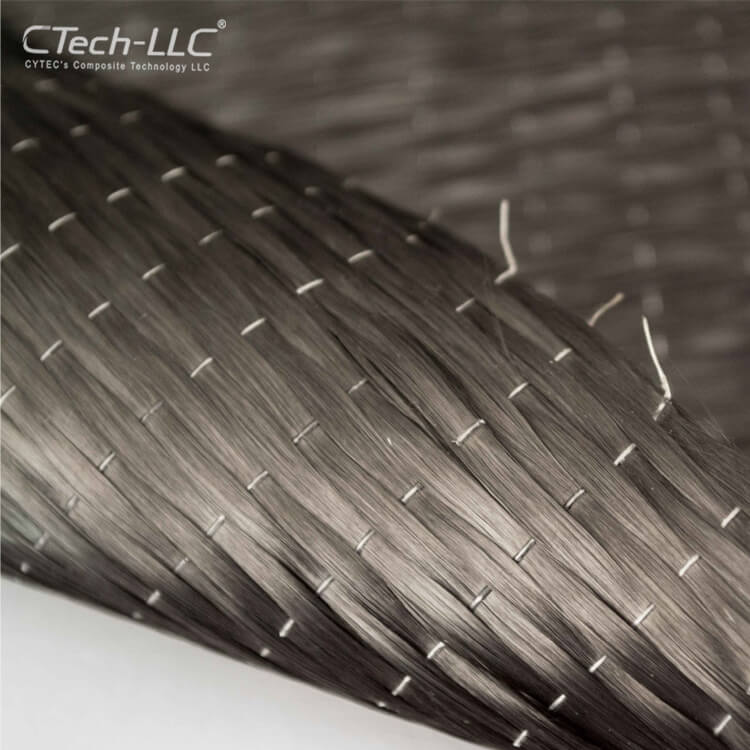

UCW™: High strength unidirectional carbon wrap with fibers oriented in the 0° direction weighing 160, 200, 230, 300 and 400 g per m².

BCW™: High strength bidirectional carbon wrap with fibers oriented in the 0° and 90° directions weighing 160, 200, 320 g per m².

Key Features

- Lightweight, flexible, high-strength fiber can be used in different surfaces like circular columns and other arched surfaces.

- Chemical and corrosion resistant.

- Compatible with different materials and standard adhesive resins.

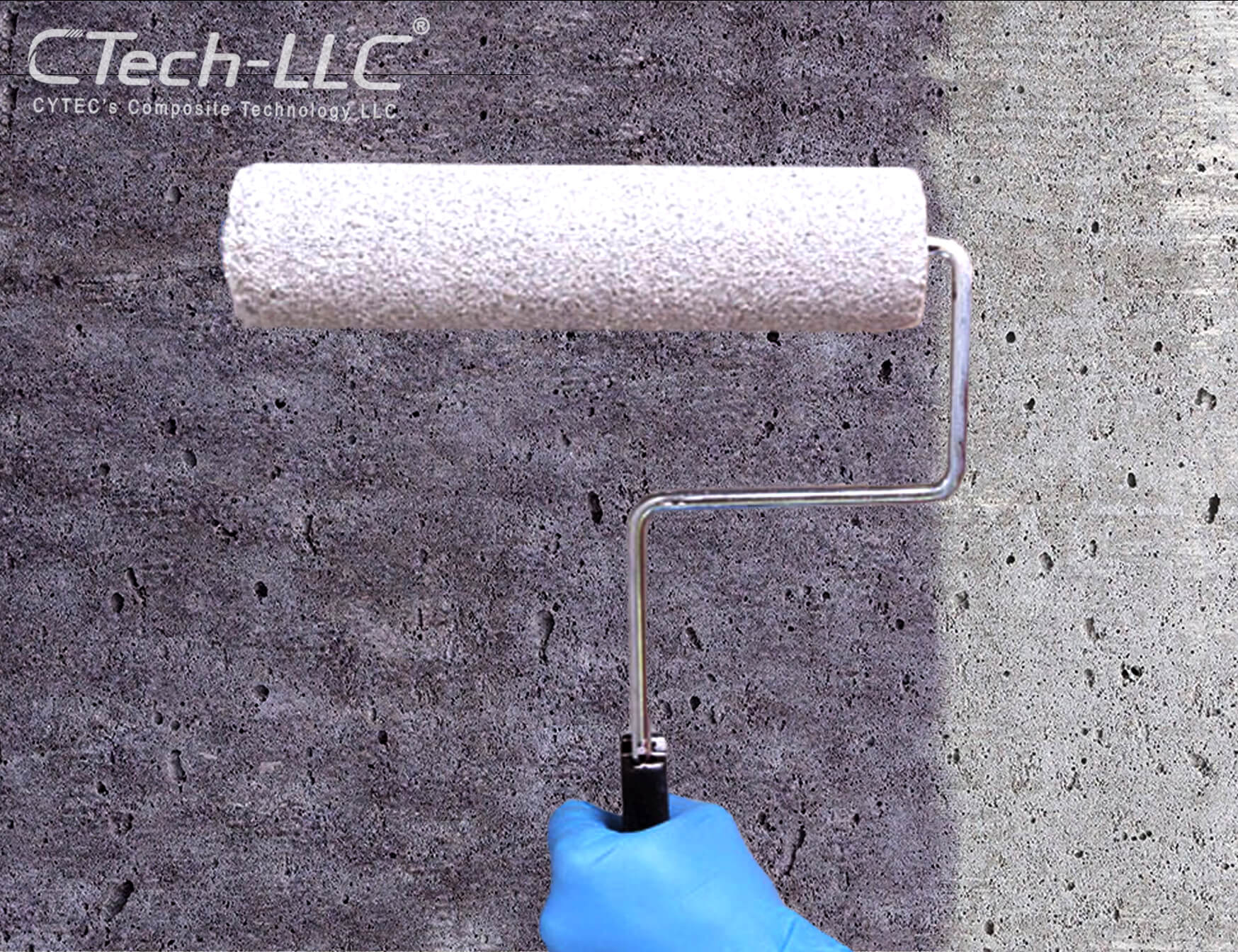

- Easy to impregnate using wet or dry lay-up methods.

- Low aesthetic impact.

Applications

- Strengthen for increasing load capacity.

- Address changes in structural system, like slab openings and walls, beams or columns removal.

- Retrofit for seismic, wind or blast.

- Restore strength of structural elements damaged by fire or vehicle impact.

- Restore strength to deteriorated and corroded members.

- Strengthen for design or construction defects.

Storage Conditions

Carbon fibers should be stored at +10°C to +40°C and should not be exposed to direct sunlight. Keep the carbon fabrics in a dry place.

Shelf Life

10 years in unopened, undamaged carton

Options

| Product Code | Unit | UCWTM3.0h | UCWTM2.0h | UCWTM1.0h |

|---|---|---|---|---|

| Roll Size (Length) | m | 50-100 | 50-100 | 50-100 |

| Roll Size (Width) | cm | 10-100 | 10-100 | 10-100 |

| Thickness | mm | 0.09 | 0.11 | 0.17 |

| Product Code | Unit | BCWTM3.0h | BCWTM2.0h | BCWTM1.0h |

|---|---|---|---|---|

| Roll Size (Length) | m | 50-100 | 50-100 | 50-100 |

| Roll Size (Width) | cm | 10-100 | 10-100 | 10-100 |

| Thickness | mm | 0.09 | 0.11 | 0.18 |

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.