Product Documents

PER™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

PER™ is a general Pure Purpose liquid Epoxy Resin with two -component, high performance, multipurpose epoxy resin formulated by CTech-LLC® works as a bonding agent for a range of indoor and outdoor applications. CTech-LLC® PER™ is a clear difunctional bisphenol A/epichlorohydrin derived liquid epoxy resin. When cross-linked or hardened with appropriate curing agents, very good mechanical, adhesive, dielectric and chemical resistance properties are obtained. Because of this versatility, CTech-LLC® PER™ has become a standard epoxy resin used in formulation, fabrication and fusion technology.

Key Features

- Medium viscosity

- High reactivity

- Good high and low temperature properties

- High Strength

- Moisture Insensitive

- Ambient cure

- Easy to apply

- Long-term durability

- Gap filling capability

- Resistant to extreme shock, vibration, and flexing

- High fatigue strength

- Low odor

Applications

- Adhesives, Casting and tooling

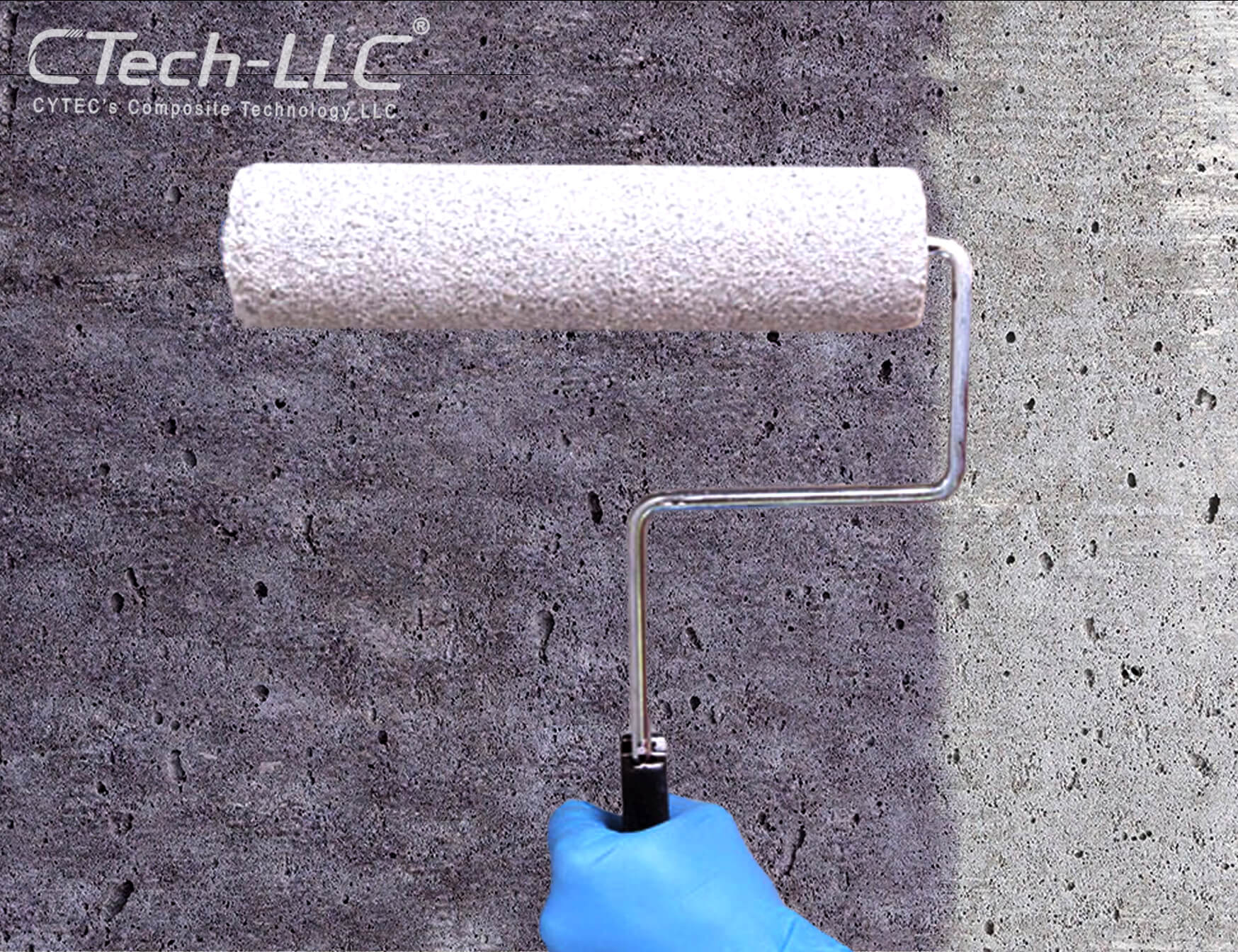

- Civil Engineering

- Composites Automotive Coatings

- Marine and Protective Coatings

- Electrical and electronics use

- Potting and Encapsulation

- Fiber reinforced pipes, tanks and composites

- Tooling, casting and molding compounds

- Construction, electrical and aerospace adhesives

- High solids/low VOC maintenance and marine coatings

- Electrical encapsulations and laminates

- Chemical resistant tank linings, flooring and grouts

- Base resin for epoxy fusion technology

Storage Conditions

PER™ is normally shipped in bulk from 66 °C to 82 °C and can be stored at 49-60 °C for ease of handling.

Shelf Life

PER™ can be stored for two years in its original packaging.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.