Product Documents

CAH™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

CTech-LLC® CAH™ Curing Agent Hardener is a medium-viscosity epoxy curing agent. It is used in a majority of situations, at lower temperatures and to produce a rapid cure that develops its physical properties quickly at room temperature. When mixed with the resin to hardener, the cured resin/hardener mixture yields a rigid, high-strength, moisture-resistant solid with excellent bonding and coating properties. Not intended for clear coating. But Slow Hardener is a low-viscosity epoxy curing agent for use when extended working and cure time is needed or to provide adequate working time at higher temperatures. When combined with resin, the cured resin/hardener mixture yields a rigid, high-strength, moisture-resistant solid with excellent bonding and coating properties. Not intended for clear coating.

CTech-LLC® CAH™ Curing Agent Hardener is used for general coating and bonding applications at lower temperatures and to produce a rapid cure that develops its physical properties quickly at room temperature.

Key Features

- Acceptable ratio range by weight 4.83:1 to 6.20:1.

- Working time, thin film about 60 to 70 minutes and Epoxy cures faster at higher temperatures and in thicker applications.

- Cure to a solid, thin film about 6 to hours and Epoxy cures faster at higher temperatures and in thicker applications.

- Cure to working strength 1 to 4 days.

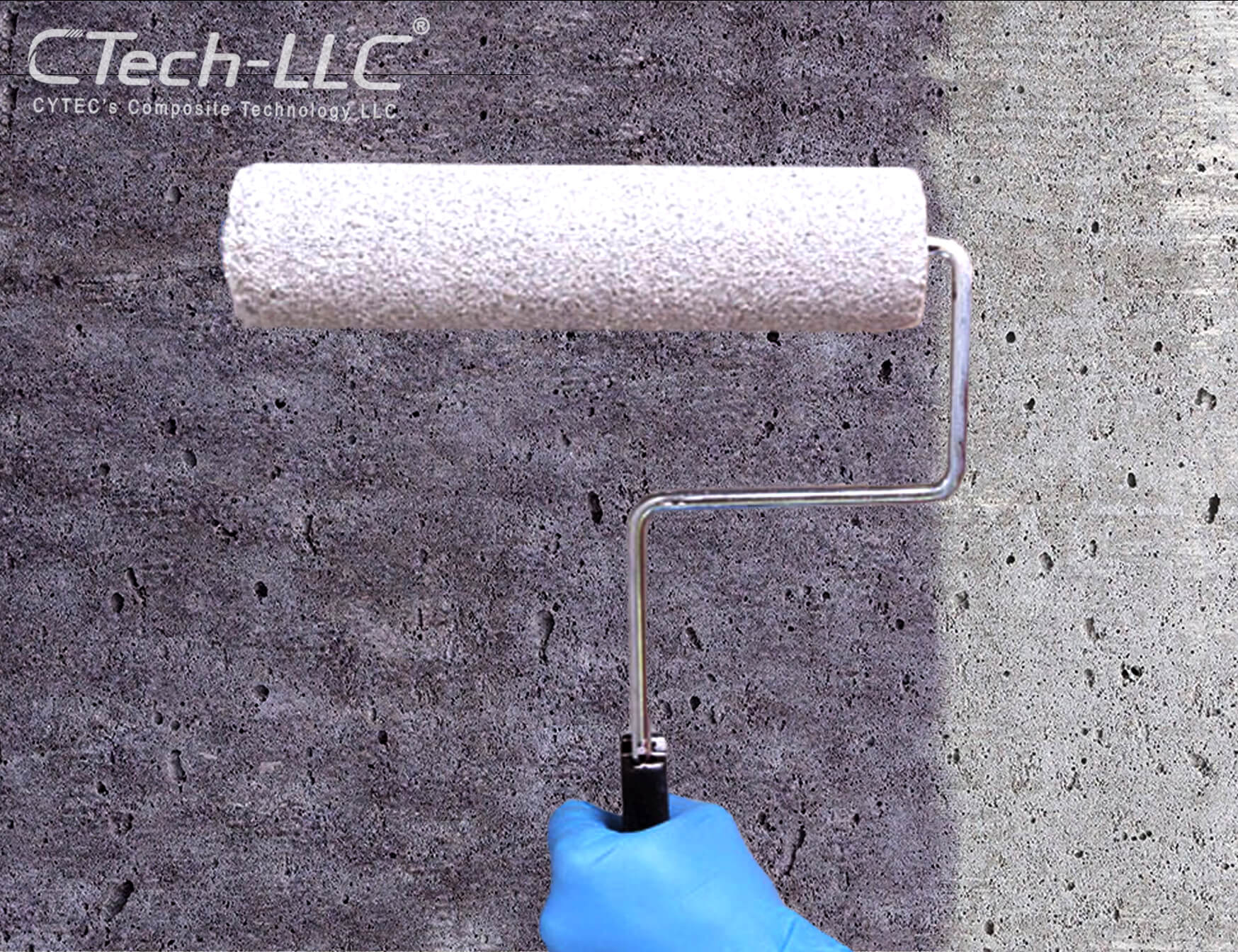

Applications

- Adhesives, Casting and tooling

- Civil Engineering

- Composites Automotive Coatings

- Marine and Protective Coatings

- Potting and Encapsulation

- Fiber reinforced pipes, tanks and composites

- Tooling, casting and molding compounds

- Construction, electrical and aerospace adhesives

- High solids/low VOC maintenance and marine coatings

- Electrical encapsulations and laminates

- Chemical resistant tank linings, flooring and grouts.

Storage Conditions

Store at room temperature. Keep containers closed to prevent contamination. With proper storage, resin and hardeners should remain usable for many years.

Shelf Life

5 years from date of production in unopened cans.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.