Product Documents

PCF™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

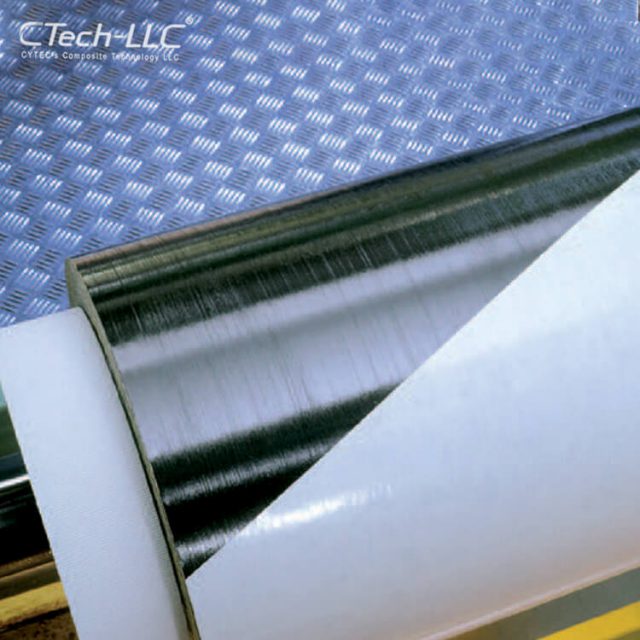

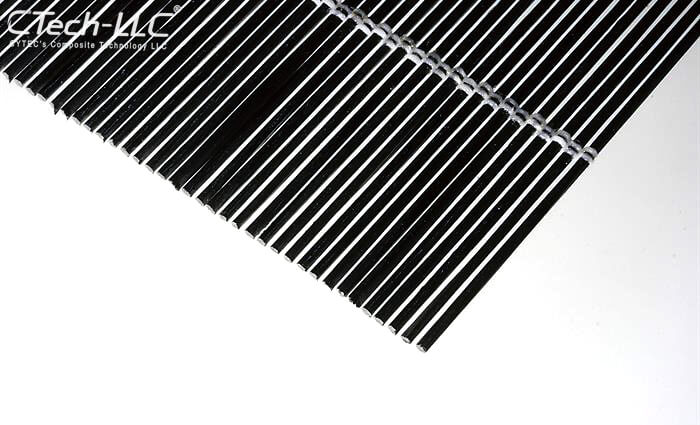

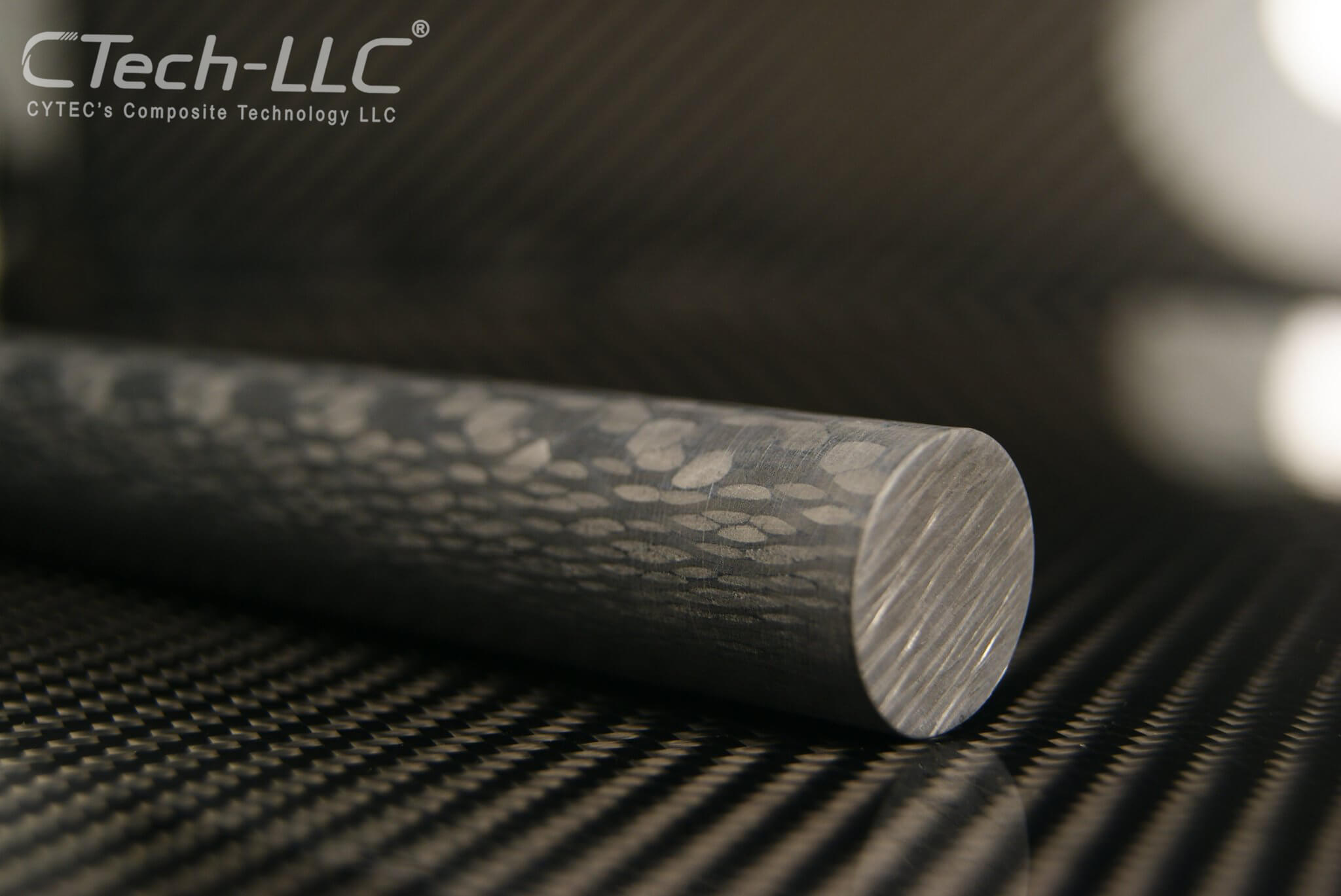

CTech-LLC produces uni-directional (UD) prepreg tapes based on CTech-LLC® UCW™ Uni-directional Carbon Wrap. CTech-LLC® PCFTM Prepreg Carbon Fiber is ideal for large volume composite applications where high production throughput, excellent composite properties, and low material cost are important. a wide selection of epoxy resin formulations meets most processing and composite property requirements for tack, toughness, surface finish, cure time, cure temperature, and delivered composite strength and modulus. Custom formulations are also available. CTech-LLC® PCF™ Prepreg Carbon Fiber properties, such as fiber areal weight, resin content, and width, are readily adjusted to exactly meet customer requirements. Packaging options include core size, customer specified kitting requirements, and custom labeling. CTech-LLC® PCF™ Prepreg Carbon Fiber production is geared to large volumes and low cost.

Key Features

- Near-perfect epoxy resin content, maximizing strength properties for the reinforcement.

- Excellent surface finish, engineered to be less porous at the surface.

- Room temperature storage, making them easier to keep and handle, without the need to thaw required of frozen prepreg options.

- Lightweight, flexible, high-strength fiber.

- Chemical and corrosion resistant.

Applications

- Advanced composites

- Used to make the chassis and body panels of Formula 1 cars.

- Wings of the latest passenger jets.

Storage Conditions

prepreg carbon fiber can be stored in the freezer and remain useable when thawed-out is known as its ‘freezer life’ or ‘shelf-life’.

- The shelf life is 6 months from the date of manufacture when the maximum storage temperature shall not exceed 32°C.

- The shelf life is 12 months from the date of manufacture when the maximum storage temperature shall not exceed 24°C.

- The shelf life is 30 months from the date of manufacture when the maximum storage temperature shall not exceed -18°C, with an

additional 6 months at <24°C.

Shelf Life

Shelf life is 3 years.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.