Product Documents

UAW™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

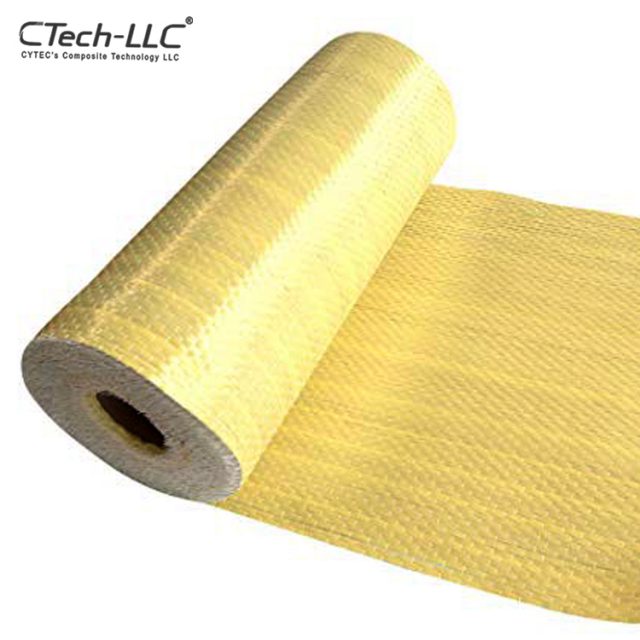

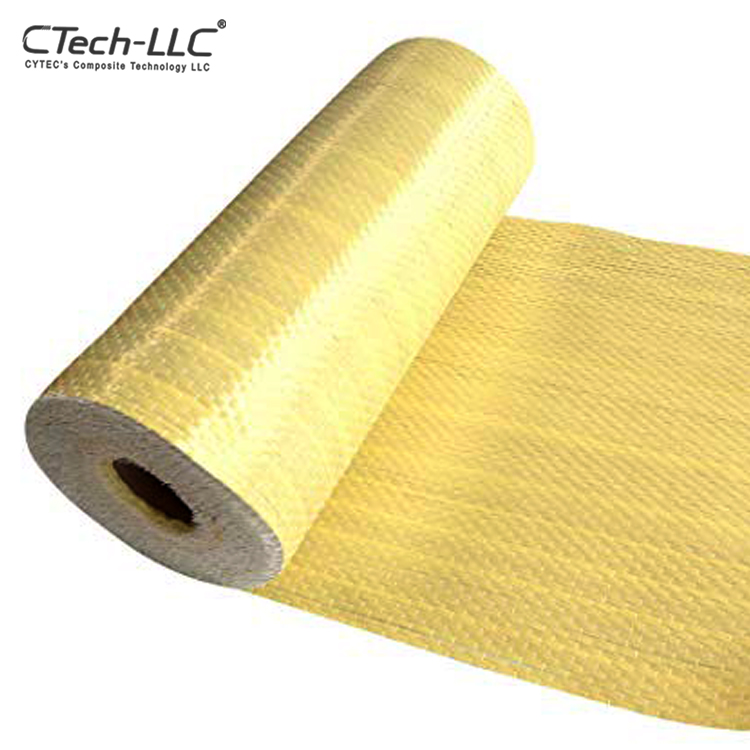

CTech-LLC® Unidirectional Aramid Wrap UAW™, or known by many as Kevlar belongs in a family of synthetic products characterized by strength some five times stronger than steel on an equal weight basis and heat-resistance some more than 500 degrees Celsius. It is appropriate for various applications such as composites, ballistics, aerospace, automotive, protective clothing against heat/radiation/chemicals, asbestos substitute, telecommunications optical fiber cables and many other.

Key Features

- High strength to weight ratio

- Low elongation to break

- Good heat & flame resistance

- Good chemical resistance

- High cut resistance

- Excellent ballistic properties

Applications

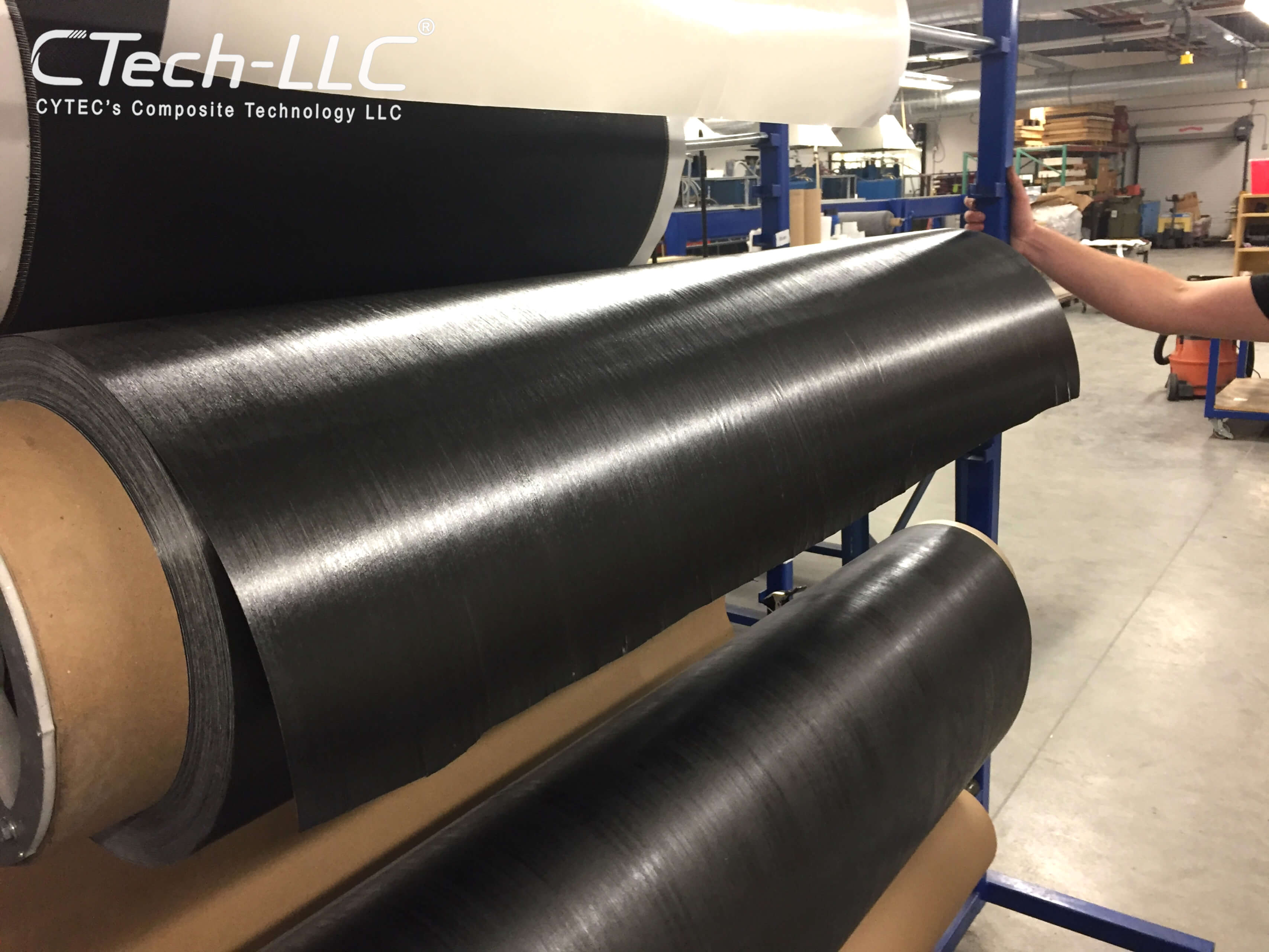

- Various forms of composite materials

- Sail cloth

- Snowboards

- Protective gloves, helmets, body armor

- Filament wound pressure vessels

- Flame and cut resistant clothing

- Asbestos replacement

- Ropes and cables

- Optical fiber cable systems

- Jet engine enclosures

- Tennis strings and hokey sticks

- Wind instrument reeds

- Reinforcement for tires and rubber goods

- Circuit board reinforcement

- Coating

- Twisting

- Extrusion

- Pultrusion

- Precision Winding

Storage Conditions

Aramid fibers should be stored at +10°C to +40°C and should not be exposed to direct sunlight.

Shelf Life

10 years in unopened, undamaged carton.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.