Product Documents

UCL™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

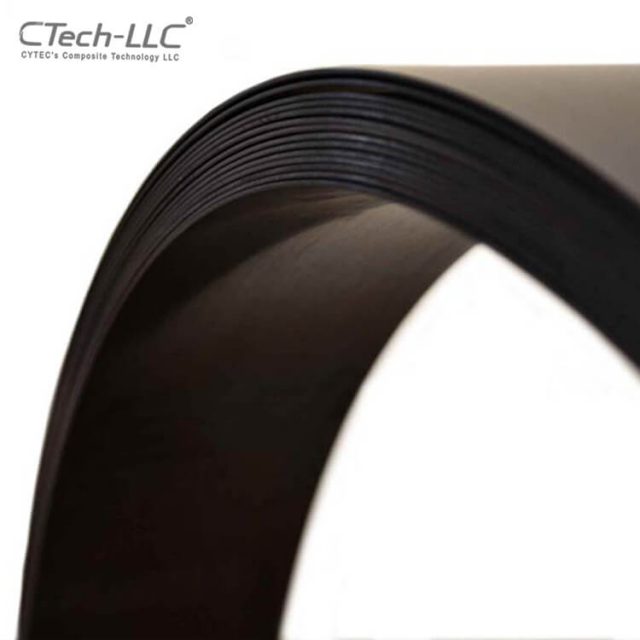

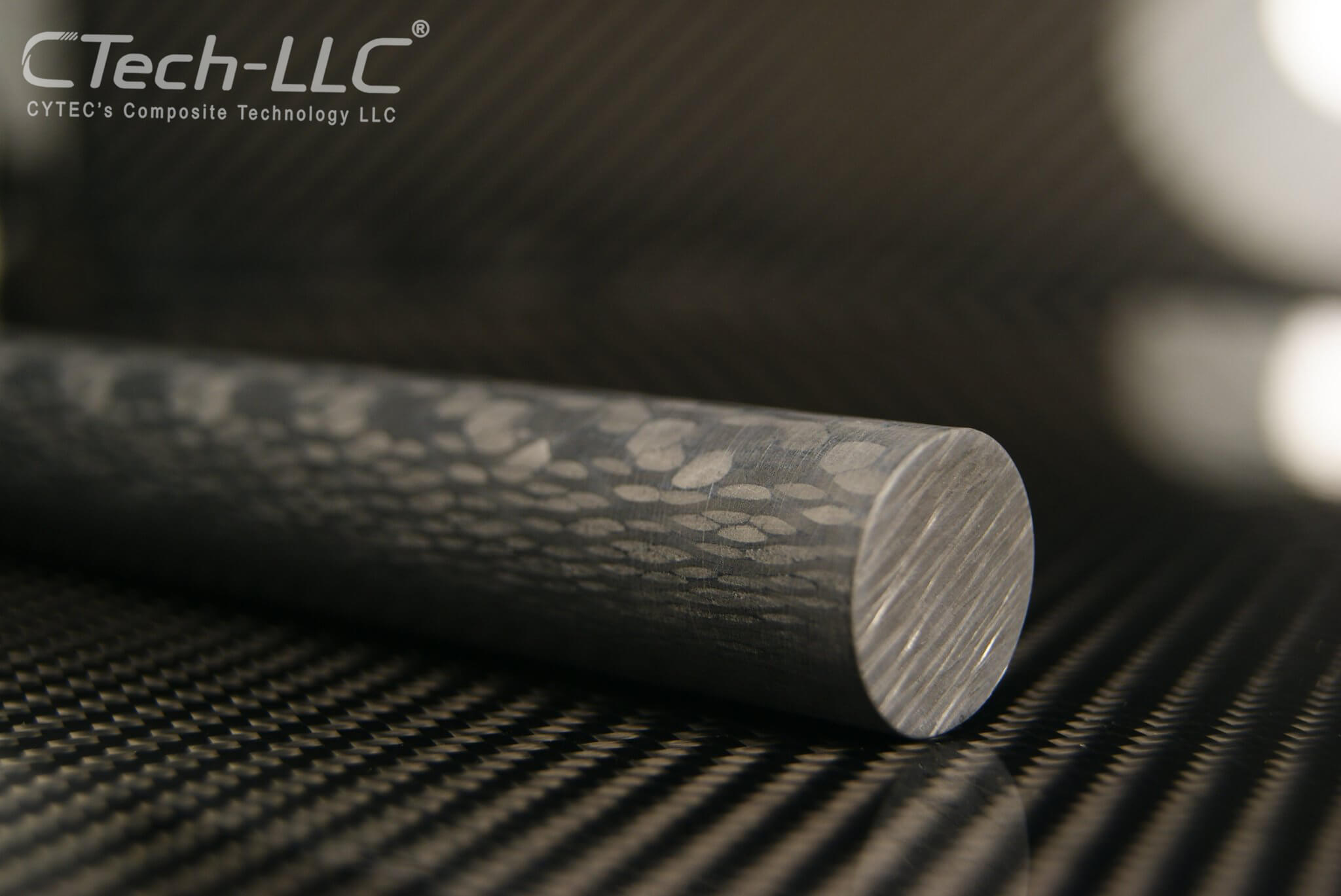

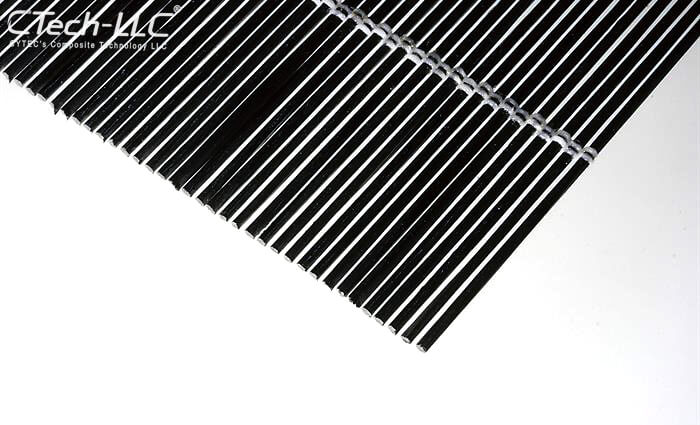

UCL™ is high-strength and light weight unidirectional pultruded laminate constructed with carbon fibers and epoxies. UCL™ carbon laminate is designed for bonding onto the structure as external reinforcement using ERA™420 epoxy resin as the adhesive.

Key Features

- Excellent fatigue resistance, chemicals resistant.

- Corrosion resistance.

- Fully compatible with different resins.

- Easy to install.

- Can be crossed and overlapped to thin section easily.

- Inspection is easy to carry out after construction

- Not harmful to the environment.

Applications

- Increased load capacity in buildings, bridges, vibrating structures, hospital floors, roofs of buildings, etc.

- Increased load capacity in case of change of building utilization.

- Seismic strengthening of structural elements such as columns, unreinforced masonry walls.

- Repairing of damaged structural components caused by aging of construction materials, Chemical environments, fire, vehicle impact, etc.

- Correction of design or construction mistakes such as insufficient reinforcements, insufficient structural depth, etc.

Storage Conditions

CTech-LLC® unidirectional carbon laminate should be stored in a dry and cool place at 4°-40° C.

Shelf Life

UCL™ can be used for unlimited time in proper storage conditions.

Options

| Product Code | Unit | UCL™5010 | UCL™10012 | UCL™5014 | UCL™10014 |

|---|---|---|---|---|---|

| Thickness | mm | 1.2 | 1.2 | 1.4 | 1.4 |

| Width | mm | 50 | 100 | 50 | 100 |

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.