Product Documents

EZP™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

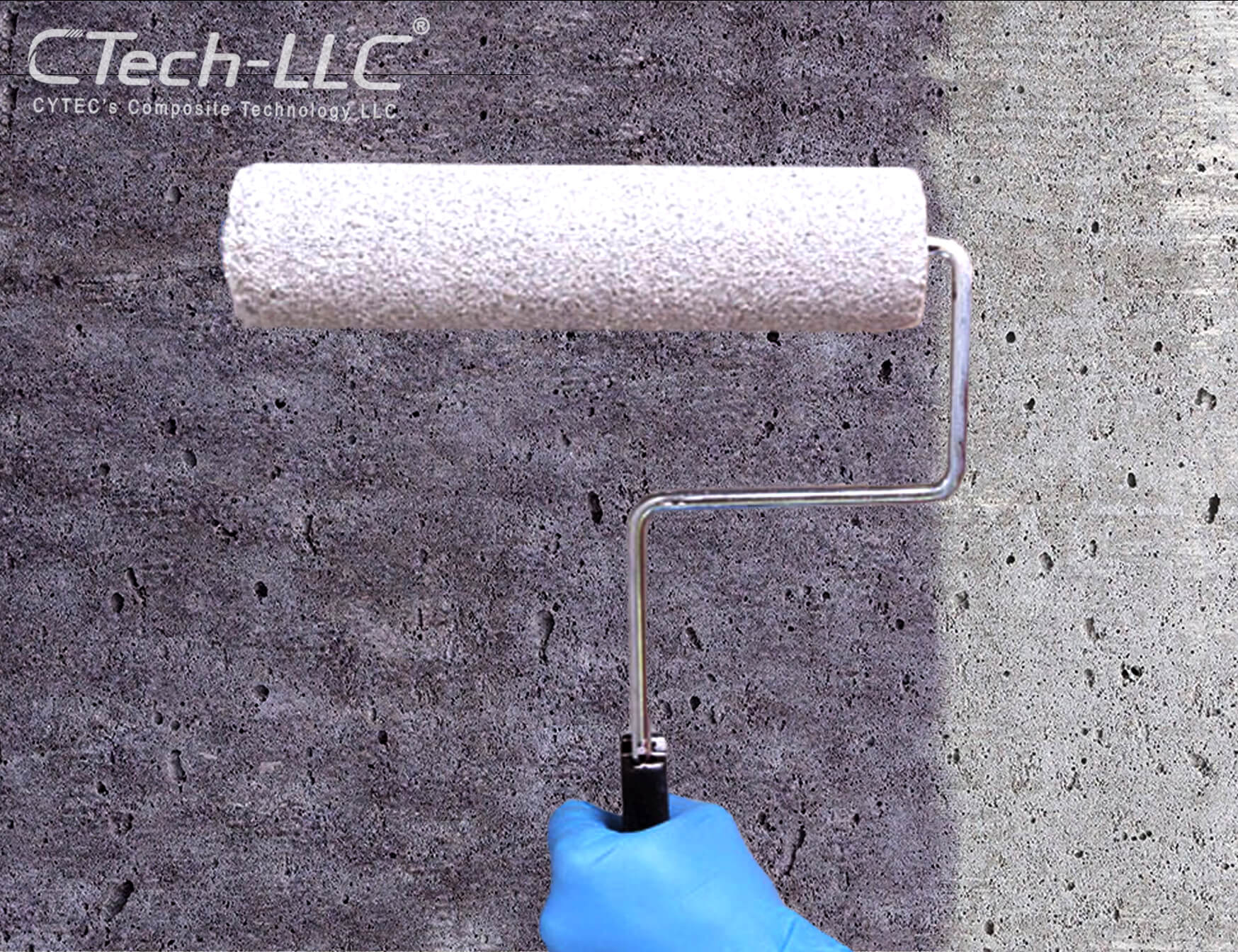

The CTech-LLC® Epoxy Zinc-Rich Primer (EZP™) is a two component, metallic zinc rich epoxy primer formulated to provide corrosion protection to steel substrates in both maintenance and new construction situations. As a high performance anti-corrosive primer, EZP™ gives maximum protection as part of any anti-corrosive coating system for aggressive environments including those found on offshore structures, petrochemical facilities, pulp and paper plants, bridges and power plants.

Key Features

- Provides excellent corrosion protection.

- No need to mist coat – saves time.

- Economical zinc rich epoxy.

- Can topcoat with a range of coating types, such as epoxies, polyurethanes, and chlorinated rubbers.

Applications

Suitable for structural steel and piping exposed a wide range of corrosive atmospheric environments. Recommended for offshore environments, refineries, power plants, bridges, buildings, mining equipment and general structural steel. Specially designed as a primer for coating systems where extended durability is required.

Storage Conditions

The material should be stored at temperatures between 5°C to 35°C to ensure shelf life.

Shelf Life

Shelf life is 18 months when stored as recommended in original unopened containers

Options

Packaging / By Weight :

- Component A = 20 kg / Component B = 10 kg

- Component A = 10 kg / Component B = 5 kg

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.