Product Documents

EPG™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

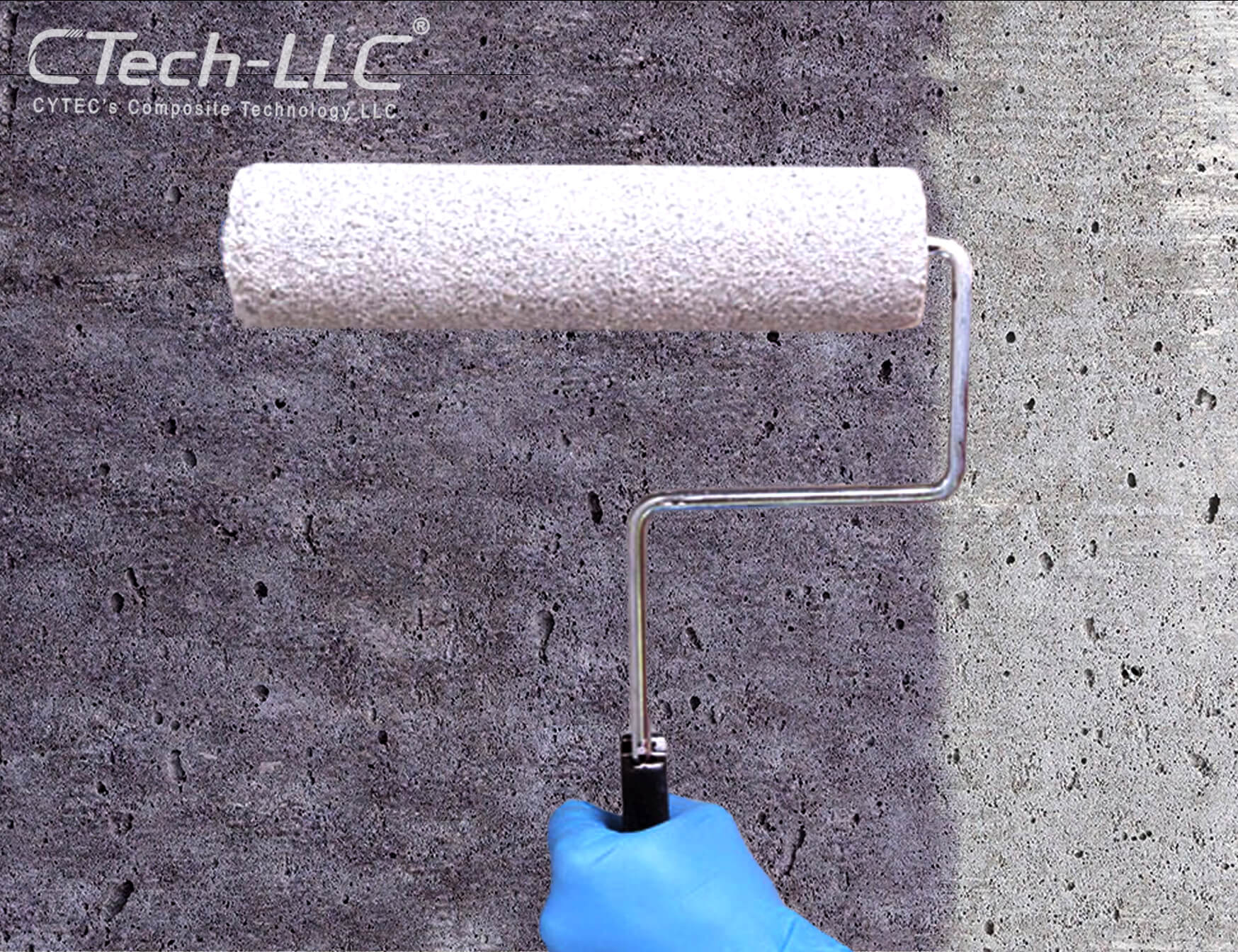

The CTech-LLC® EPG™ is an epoxy resin gelcoat for use as a surface coat when making frp based composite parts and gfrp lining of structures.

The CTech-LLC® EPG™ epoxy gelcoat works as the external coat of one of the surfaces of the laminate, providing protection against chemicals, weathering, humidity or any aggression from the environment.

Key Features

- Color quality and stability

- High chemical resistance

- Excellent resistance to a multitude of chemicals

- Heat resistance

- Resistance to abrasion and corrosion

- Resistance to the action of UV radiation and temperature changes

- Can be used where drinking water approval is needed

- Hardly present volumetric shrinkage

Applications

- The manufacturing of reinforced parts and moulds/tools with thermosetting epoxy resins.

- Gelcoat for GFRP lining of storage tanks, pipelines etc.

Storage Conditions

- EPG™ epoxy gel coat and hardener should be kept in tightly sealed containers during transport and storage. Both the gelcoat and hardener should be stored in ambient conditions of between 4°C and 40°C.

- When stored correctly, the resin and hardener will have a shelf-life of 18 months..

Shelf Life

- When stored correctly, the resin and hardener will have a shelf-life of 18 months.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.