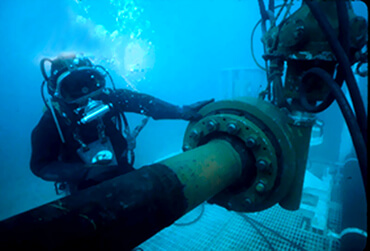

FRP Composite Repair System for Underwater Applications

The SubSea PipeWrap™ is a pre-preg, high performance water-activated composite system used to reinforce and repair pipeline and piping structures in wet or underwater conditions. The SubSea PipeWrap™ is comprised of a high strength fiberglass fabric that is factory impregnated with a moisture cured polyurethane resin system. The advanced composite repair system sets within an hour after installation and reinforce defective pipelines and piping systems in both the hoop and axial directions. With considerable advantages over conventional systems, the SubSea PipeWrap™ system is most commonly used for leak containment or as a reinforcing repair to restore the strength of pipelines and piping systems that have suffered from corrosion or mechanical damages. Multiple repair issues include:

- Corrosion

- Dents

- Leaks

- Cracks

- Manufacturing Flaws

Because of its thin, low-profile, the innovative composite solution can wrap pipe configuration including tees, elbows, straight runs, 90’s and complex curved and irregular surfaces that require structural reinforcement or repair.