Product Documents

EIR™ - Technical Data Sheet Safety Data SheetFor more information regarding CTech-LLC® products, please contact our team by clicking here.

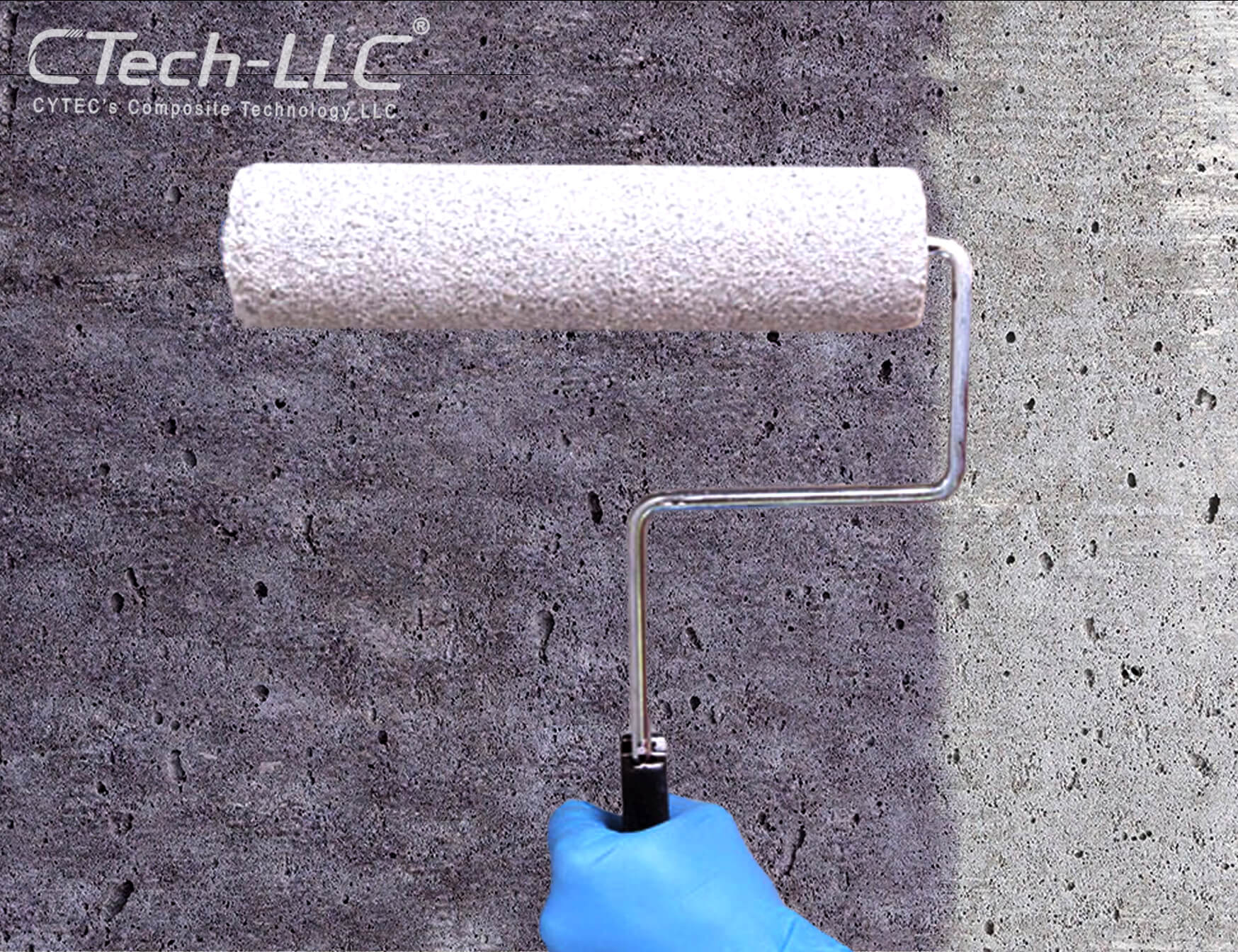

EIR™ is a two-component, 100% solids, high strength, solvent-free epoxy resin for crack injection. Due to its high rate of penetration into porous substrates and excellent adhesion to concrete and masonry, EIR™ provides for permanent bonding even of smallest cracks and restores structural integrity.

Key Features

- Low-viscosity consistency for deep penetration of concrete cracks.

- Good chemical resistance to protect concrete slabs and decks.

- Resistance to creep and stress.

- Low odor formulation.

- Shrinkage free hardening.

- High mechanical and fatigue strength.

- Cures even under dynamic stress.

Applications

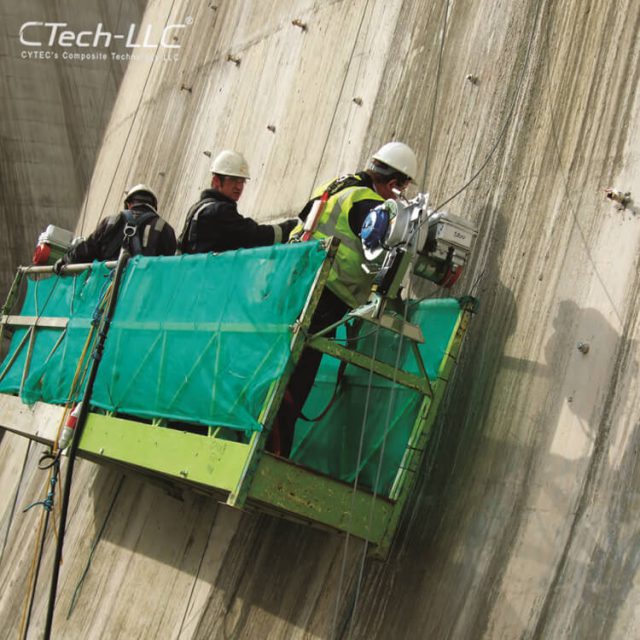

- Pressure-inject horizontal, vertical or overhead cracks for a structural repair of concrete & masonry structures.

- Mix with aggregate to repair concrete spalls and voids as an epoxy repair mortar.

- Use to fill and seal voids and cracks in structures such as bridges and other civil engineering buildings, industrial and residential buildings, columns, beams, foundations, walls, floors and water retaining structures.

- Bonding of structural elements

- Consolidating steel sheet injection.

- Solidification of hollow core screed.

- Injection of construction joints.

- Solidification of open-poured concrete structures.

Storage Conditions

CTech-LLC® EIR™ resin should be stored in a dry and cool place at 4° to 40° C. Avoid freezing the product and keep it away from direct sunlight, flame or other hazards.

Shelf Life

With proper storage, EIR™ can be stored for three years in its original packaging.

Options

Packaging / By Weight :

- Component A = 20 kg / Component B = 2.6 kg

- Component A = 10 kg / Component B = 1.3 kg

***Note: Customized packaging is also available.

Codes and Standards

Waranty

CTech-LLC® warrants its products to be free from manufacturing defects. Buyer determines suitability of product for use and assumes all risks. Buyer’s sole remedy shall be limited to replacement of product. Any claim for breach of this warranty must be brought within one month of the date of purchase. CTech-LLC® shall not be liable for any consequential or special damages of any kind, resulting from any claim or breach of warranty, breach of contract, negligence or any legal theory. The Buyer, by accepting the products described herein, agrees to be responsible for thoroughly testing any application to determine its suitability before utilizing.